First

step is to put the shock mount flanges back on the upper

arms. The bolts were good enough to reuse but I bought

new lock washers

First

step is to put the shock mount flanges back on the upper

arms. The bolts were good enough to reuse but I bought

new lock washers |

Finally

got the steering knuckles and spindles back from the machine

shop. They did a nice job but they managed to destroy

the other spacer. I could have done that myself...

I cleaned and degreased all the bearings to get the

preservative goop out.

Finally

got the steering knuckles and spindles back from the machine

shop. They did a nice job but they managed to destroy

the other spacer. I could have done that myself...

I cleaned and degreased all the bearings to get the

preservative goop out. |

Now

I can fit the kingpins to the control arms. Here I

have the new pin and rubber rings installed and I am

installing the metal wedge that keeps the pin from turning

inside the kingpin.

Now

I can fit the kingpins to the control arms. Here I

have the new pin and rubber rings installed and I am

installing the metal wedge that keeps the pin from turning

inside the kingpin. |

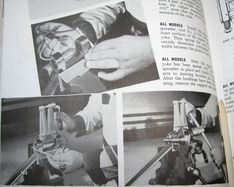

This

bad picture from the manual shows the special tool

Studebaker used to keep the arm from flexing as the pin is

tightened. I don't have this tool so this is my

homebrew version make from a 5/8" bolt and some nuts and

washers. I wonder if it will work...

This

bad picture from the manual shows the special tool

Studebaker used to keep the arm from flexing as the pin is

tightened. I don't have this tool so this is my

homebrew version make from a 5/8" bolt and some nuts and

washers. I wonder if it will work... |

The

manual says to use the tool to spread the arm .010" then

install the end caps. I could not get it to open up

that much but it did move. I think the goal here is to

keep the caps from flexing the arm when they are tightened.

This could cause the pin to bind.

The

manual says to use the tool to spread the arm .010" then

install the end caps. I could not get it to open up

that much but it did move. I think the goal here is to

keep the caps from flexing the arm when they are tightened.

This could cause the pin to bind.

Next it is big wrench time. I was not sure now this

was supposed to work so I centered the pin by eye then

tightened the caps a little at a time switching sides |

Looks

like a winner. The pin is tight with no wiggle but

moves freely. I packed the upper thrust bearing with

grease and installed the bearing and shims. I also

tightened the grease fittings in the caps.

Looks

like a winner. The pin is tight with no wiggle but

moves freely. I packed the upper thrust bearing with

grease and installed the bearing and shims. I also

tightened the grease fittings in the caps. |

This

cork gaskets goes in the yoke that holds the kingpin in the

spindle. The cork gasket is old stock and cracked when

I installed it. Still it should work OK. The

yoke has a keyway for a

woodruff key on the end of the kingpin.

This

cork gaskets goes in the yoke that holds the kingpin in the

spindle. The cork gasket is old stock and cracked when

I installed it. Still it should work OK. The

yoke has a keyway for a

woodruff key on the end of the kingpin. |

After

greasing the needle bearing and bushing the spindle slides

right on. Here the yoke is in place but the washer and

nut are not yet installed.

After

greasing the needle bearing and bushing the spindle slides

right on. Here the yoke is in place but the washer and

nut are not yet installed. |

The

finished product. The yoke is in place, nut tightened, and

a new cotter pin installed. I also installed the grease

fitting in the spindle. Now I get to repeat on the other

side and the arms are ready to go back in the car.

The

finished product. The yoke is in place, nut tightened, and

a new cotter pin installed. I also installed the grease

fitting in the spindle. Now I get to repeat on the other

side and the arms are ready to go back in the car. |

The

other (drivers) side. This one went back together pretty

much the same except I used too many shims on the kingpin and

had to take it apart again to fix it. I carefully measured

for the shims but ended up removing all of them. I am not

sure what happened but it feels great so I am leaving it be.

The

other (drivers) side. This one went back together pretty

much the same except I used too many shims on the kingpin and

had to take it apart again to fix it. I carefully measured

for the shims but ended up removing all of them. I am not

sure what happened but it feels great so I am leaving it be. |

Here

are all the parts to install the control arm in the driver's

side. From left to right we have the front mount and its

bolts, the new front bushings, the bushing hardware, the shims,

the control arm and spindle, and rear bushings and hardware.

Here

are all the parts to install the control arm in the driver's

side. From left to right we have the front mount and its

bolts, the new front bushings, the bushing hardware, the shims,

the control arm and spindle, and rear bushings and hardware. |

It

is easier to work on this stuff out of the car so I installed

the front mount and bushings on the floor. The bolt is

only loosely installed because I don't want to clamp the

bushings in place until I have the arm positioned properly.

I also slipped the inner rear bushing on.

It

is easier to work on this stuff out of the car so I installed

the front mount and bushings on the floor. The bolt is

only loosely installed because I don't want to clamp the

bushings in place until I have the arm positioned properly.

I also slipped the inner rear bushing on. |

Tap

the bolts though, slip the rear of the arm in the rear mount,

and install the front mount very loosely. Everything is

going smoothly so far.

Tap

the bolts though, slip the rear of the arm in the rear mount,

and install the front mount very loosely. Everything is

going smoothly so far. |

The

last (rear) bushing slipped right in so I reinstalled the shims

under the front mount and cranked the front mount bolts tight.

You can see the shims clearly in the right picture.

The

last (rear) bushing slipped right in so I reinstalled the shims

under the front mount and cranked the front mount bolts tight.

You can see the shims clearly in the right picture. |

Bushing

and frame bolts are tight and everything looks good. Time

to install a shock.

Bushing

and frame bolts are tight and everything looks good. Time

to install a shock. |

Bolting

the shock in place is easy enough. one of the bolts was

pretty corroded so I replaced it with a new grade 5 nut and

bolt. Now for the tricky part. The shock arm to

frame hardware is in the picture on the right. I have new

isolation bushings and a new upper washer too.

Bolting

the shock in place is easy enough. one of the bolts was

pretty corroded so I replaced it with a new grade 5 nut and

bolt. Now for the tricky part. The shock arm to

frame hardware is in the picture on the right. I have new

isolation bushings and a new upper washer too. |

Now

things are getting interesting. At left you can see the

hole in the wheel well required to snake this very long bolt

through the bushings, shock arm, and frame rail. But this

bolt is not long enough. The end of the bolt does not

reach the bottom of the frame. Now

things are getting interesting. At left you can see the

hole in the wheel well required to snake this very long bolt

through the bushings, shock arm, and frame rail. But this

bolt is not long enough. The end of the bolt does not

reach the bottom of the frame.

|

Here

is the last surviving old bushing. The idea is the dished

washers and bolt squish the cylindrical bushings into this UFO

shape. But I am not sure how to get the bolt shoved though

enough to get the nut on. Maybe someone pushing from above

can compress it enough. I will try it tomorrow. Time

for bed. Here

is the last surviving old bushing. The idea is the dished

washers and bolt squish the cylindrical bushings into this UFO

shape. But I am not sure how to get the bolt shoved though

enough to get the nut on. Maybe someone pushing from above

can compress it enough. I will try it tomorrow. Time

for bed. |

OK,

a new day and a new attempt. Let's see how things are

supposed to work. I put the old shock on the bench and

used a shorter bolt to pull things together. Looks like I

am trying to do the right thing here.

OK,

a new day and a new attempt. Let's see how things are

supposed to work. I put the old shock on the bench and

used a shorter bolt to pull things together. Looks like I

am trying to do the right thing here.

|

My

first thought was to put a bar clamp or big channel locks on the

bolt and squeeze it down. But I could not find an

angle that would work. Then I found that I could put the

bar clamp on the arm of the shock. So I took out the upper

bushing to get some working room, pulled the lower bushing flat,

and used the bar clamp to hold it in the squished position. My

first thought was to put a bar clamp or big channel locks on the

bolt and squeeze it down. But I could not find an

angle that would work. Then I found that I could put the

bar clamp on the arm of the shock. So I took out the upper

bushing to get some working room, pulled the lower bushing flat,

and used the bar clamp to hold it in the squished position.

|

I

then put the top bushing back in. I still could not get

the nut on so I had my daughter push on the top of the

bolt with a long metal rod. That did it! I cranked

that sucker down. It looks great. In an attempt to

make this easier on the other side I put those bushings in my

test rig and left them squished. Maybe it will help. I

then put the top bushing back in. I still could not get

the nut on so I had my daughter push on the top of the

bolt with a long metal rod. That did it! I cranked

that sucker down. It looks great. In an attempt to

make this easier on the other side I put those bushings in my

test rig and left them squished. Maybe it will help. |

I

installed the control arm and spindle on the passenger side.

That went the same as the driver's side except I still have not

found a shock absorber so that fun step is deferred for now.

I then went to install the lower pin though the spring.

The manual is very clear that the spring should be centered in

the yoke before putting the pin in. On the driver's side

it lined up perfectly. However on the passenger side I

could not even get the yoke over the spring. After some

head scratching I figured out that the only way to make this

work is to move the spring. I

installed the control arm and spindle on the passenger side.

That went the same as the driver's side except I still have not

found a shock absorber so that fun step is deferred for now.

I then went to install the lower pin though the spring.

The manual is very clear that the spring should be centered in

the yoke before putting the pin in. On the driver's side

it lined up perfectly. However on the passenger side I

could not even get the yoke over the spring. After some

head scratching I figured out that the only way to make this

work is to move the spring.

|

The

spring is held to the frame by these U-bolts. I loosened

them up then took a ball-peen hammer and a block of wood to the

end of the spring to try and shift it. It moved a tiny,

tiny bit. The problem with hitting a spring is that it is

a spring. It is designed to absorb energy and

return to shape. So I got out the REAL hammer. That

worked! As you can see above the yoke is almost perfectly

centered.

The

spring is held to the frame by these U-bolts. I loosened

them up then took a ball-peen hammer and a block of wood to the

end of the spring to try and shift it. It moved a tiny,

tiny bit. The problem with hitting a spring is that it is

a spring. It is designed to absorb energy and

return to shape. So I got out the REAL hammer. That

worked! As you can see above the yoke is almost perfectly

centered. |

The

pin has this locking plate. When I took it apart I could

not figure out what good it did but I was very careful to

replace it just the way it was when I removed it. I

must be really dense because it was not until I had the pin

installed that I realized how this was supposed to work.

So I took the pin back out, flipped the plate, and reinstalled.

Some nimrod before me had installed the plates wrong. This

looks much better. But now I have another problem... The

pin has this locking plate. When I took it apart I could

not figure out what good it did but I was very careful to

replace it just the way it was when I removed it. I

must be really dense because it was not until I had the pin

installed that I realized how this was supposed to work.

So I took the pin back out, flipped the plate, and reinstalled.

Some nimrod before me had installed the plates wrong. This

looks much better. But now I have another problem... |

The

#*$&@& pin has play in it! When I took all this apart I

cleaned and inspected the pins but totally failed to notice how

badly worn they are. I am not doing all this work to leave

slop in the suspension so now this job is on hold until I can

get new pins. Looks like a couple of vendors have them

(whew!). I am hoping I can get away with just replacing

the pin. If I have to get new bushings in the spring that

will be a whole new world of suck. I am taking that gamble

because when I put the pin in just a little it seems tight.

If the bushings are cheap enough I might pick them up just in

case. The

#*$&@& pin has play in it! When I took all this apart I

cleaned and inspected the pins but totally failed to notice how

badly worn they are. I am not doing all this work to leave

slop in the suspension so now this job is on hold until I can

get new pins. Looks like a couple of vendors have them

(whew!). I am hoping I can get away with just replacing

the pin. If I have to get new bushings in the spring that

will be a whole new world of suck. I am taking that gamble

because when I put the pin in just a little it seems tight.

If the bushings are cheap enough I might pick them up just in

case. |

The

new pins and bushings arrived so we can get back to work.

As I suspected the old bushings are pretty good. I ran the

new pins in the old bushings and compared the play to the new

bushing. There is certainly more play in the old bushing

but not enough to make it worth messing with. The bushings

were about $8 each so I will just keep them. The

new pins and bushings arrived so we can get back to work.

As I suspected the old bushings are pretty good. I ran the

new pins in the old bushings and compared the play to the new

bushing. There is certainly more play in the old bushing

but not enough to make it worth messing with. The bushings

were about $8 each so I will just keep them.

|

Again

the manual makes it very clear that the yoke is supposed to be

centered in over the spring and yet when I put the new pin in I

was not paying attention and did this. Stupid. I

took the pin out, whacked the spring a couple times, and tried

again. Much better the second time.

Again

the manual makes it very clear that the yoke is supposed to be

centered in over the spring and yet when I put the new pin in I

was not paying attention and did this. Stupid. I

took the pin out, whacked the spring a couple times, and tried

again. Much better the second time. |

And

the other side...

And

the other side... |

Now

the control links can go in. It took a little tweaking to

get everything lined up but it looks great. I also

re-tightened the spring u-bolts Now

the control links can go in. It took a little tweaking to

get everything lined up but it looks great. I also

re-tightened the spring u-bolts |

Next

I can hook up the tie rod ends. The driver's side outer

tie rod end had a badly worn cover. This is where not

throwing anything way comes in handy. Here is my

collection of old tie rod ends. The middle one has a torn

up cover but the top and bottom ones look good. On the

right we have the lucky winner. Next

I can hook up the tie rod ends. The driver's side outer

tie rod end had a badly worn cover. This is where not

throwing anything way comes in handy. Here is my

collection of old tie rod ends. The middle one has a torn

up cover but the top and bottom ones look good. On the

right we have the lucky winner. |

There!

That looks good. This is the drivers side. The other

side is going to wait until the shock is installed. There!

That looks good. This is the drivers side. The other

side is going to wait until the shock is installed. |

Before

reinstalling the brakes I greased everything up. The zerk

on the front side leaked a little. I did not have it tight

enough.

Before

reinstalling the brakes I greased everything up. The zerk

on the front side leaked a little. I did not have it tight

enough.

|

The

finished product

I also finally found a passenger side shock absorber. I

cleaned and painted it. The new shock will get installed

as soon as the paint dries. but until then

The

finished product

I also finally found a passenger side shock absorber. I

cleaned and painted it. The new shock will get installed

as soon as the paint dries. but until then

|

Yet

another shot of the brakes. We are a brake drum and tire

away from putting this down on the ground. The other side

went together pretty much the same. The shock mount was

just as much of a pain

Yet

another shot of the brakes. We are a brake drum and tire

away from putting this down on the ground. The other side

went together pretty much the same. The shock mount was

just as much of a pain |

It

is a car again. The garage floor was TRASHED but I

forgot to take a picture. Hopefully I can get an alignment

this week and the car is done. It

is a car again. The garage floor was TRASHED but I

forgot to take a picture. Hopefully I can get an alignment

this week and the car is done. |