It took longer than I hoped to get to it but I finally got moving again on this conversion.

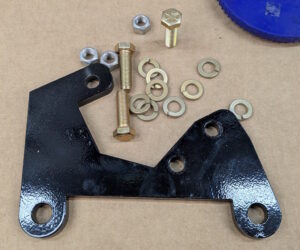

I read the instructions carefully and still managed to put this together wrong. When I tried to put the rotor on the bracket did not clear. A quick e-mail to Jim Turner cleared this up.

I need to decide what to do next. I could permenantly install the right side but I kind of want to test-fit the left just in case there is a big problem. It would be easy to put the old brakes back on at this point but once everything is torqued and has Lock-Tite on it that will be a lot more work. I should resume this tomorrow.