February, 2005

Everybody has things that they worry about. When I am driving the Stude I worry about the weak brakes, sloppy steering, lack of seatbelts, and the clueless looks I get from other drivers when I use hand signals. After seeing countless people think I am pointing when I signal a left turn it occurred to me that getting rear-ended is a real possibility. The brake lights work but like all the lights on the car they are tiny and dim by today’s standards. Click here to see what I am talking about. Brighter brake lights would make me feel better and I can work on them in my warm house. What more can I ask for?

6V bulbs are not really a growth market and are a little hard to find. I really wanted LED taillights but those are 12V only and tend to point the wrong direction. The lamp sockets on my taillights hold the bulbs straight up and down. A standard flashlight-style LED bulb would be pointing right up at the trunk lid.

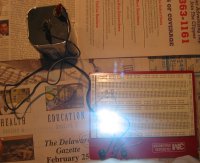

Halogen bulbs can be had but that seemed too easy. I figured I would make a 6 volt LED lamp myself using the new super-bright LED’s. The first task was to find LED’s. Turns out that they are expensive from electrical supply places in small quantities. I almost gave up when I found a deal on SnapGone for small LED keychain flashlights. These sell in stores for $3 or so but I could buy 10 for 5$. .50 each was less than I could buy just the LED’s for. I bought 30. Should have got 40.

Pingback: CHMSL in the Studebaker | 1941 Studebaker Champion