9/12/2009-9/15/2009

This summer since I finished the engine work has been swamped. I have been to exactly two car shows so far. Two weeks ago the kids and I drove to the Sertoma car show in Westerville, OH. While I was setting the car up for the show I spotted some MORE issues. Last weekend it rained so I did not get to work on anything until this weekend.

When I opened the hood the new cowl seal ripped right off the car. Why? When I opened the hood the new cowl seal ripped right off the car. Why? |

It looks like something stuck the seal to the bottom of the hood. Looks like black sticky stuff. What is on the hood? It looks like something stuck the seal to the bottom of the hood. Looks like black sticky stuff. What is on the hood? |

Ugh! There are remains of the old cowl seal stuck on the hood. These are rock-hard now that everything is cold. Apply heat and everything gets goopy. That glued the hood to the cowl seal. I scraped off as much of this as I could then I used a rag and some kerosene to clean the debris off. That should solve the problem Ugh! There are remains of the old cowl seal stuck on the hood. These are rock-hard now that everything is cold. Apply heat and everything gets goopy. That glued the hood to the cowl seal. I scraped off as much of this as I could then I used a rag and some kerosene to clean the debris off. That should solve the problem |

The passenger side of the seal peeled loose too. This was just me not putting enough glue on. Both loose spots got re-glued. The passenger side of the seal peeled loose too. This was just me not putting enough glue on. Both loose spots got re-glued. |

This oil on the engine block got my attention. I thought maybe the oil filter return line (the silver line wrapping around in this picture) was leaking. I could find nothing so I probably just sloshed some oil when I filled the engine. The same rag and kerosene I used on the hood cleaned this right up. This oil on the engine block got my attention. I thought maybe the oil filter return line (the silver line wrapping around in this picture) was leaking. I could find nothing so I probably just sloshed some oil when I filled the engine. The same rag and kerosene I used on the hood cleaned this right up. |

There was more oil on the passenger side engine tin. It was just a few drops. Turns out the oil pressure gauge line (the copper tube in the picture) is dripping. I tightened it down a bit. Hopefully that fixed the problem. That rag got used a third time to wipe up the mess.I did not get a picture of it but the lower radiator hose was seeping at the radiator connection. I just tightened the hose clamp. There was more oil on the passenger side engine tin. It was just a few drops. Turns out the oil pressure gauge line (the copper tube in the picture) is dripping. I tightened it down a bit. Hopefully that fixed the problem. That rag got used a third time to wipe up the mess.I did not get a picture of it but the lower radiator hose was seeping at the radiator connection. I just tightened the hose clamp. |

This is the heat riser again. It is frozen in position (I can’t even budge it). You can see the bi-metallic thermostat spring is totally off the pin. Time to pull this out. This is the heat riser again. It is frozen in position (I can’t even budge it). You can see the bi-metallic thermostat spring is totally off the pin. Time to pull this out. |

|

The heat riser shaft simply froze in place in no time. I think the hole in the plate will need to be reamed out a little. |

A machinist at work milled the heat riser plate for me. The only hitch was the part moved a bit so there is a bit of a taper now. A machinist at work milled the heat riser plate for me. The only hitch was the part moved a bit so there is a bit of a taper now. |

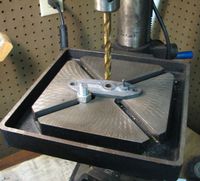

I put the part flat on the table of my drill press and chased out the hole a couple of thousandths larger. This also squared the hole to the new flat surface of the iron. I put the part flat on the table of my drill press and chased out the hole a couple of thousandths larger. This also squared the hole to the new flat surface of the iron. |

I put everything back together. I reused the gasket since it was not damaged. Everything works free and easy. I will check on it when it has been through a few heat cycles. I put everything back together. I reused the gasket since it was not damaged. Everything works free and easy. I will check on it when it has been through a few heat cycles. |

That is the one I used. It is not great but it works.